We have sole distribution rights for Africa

Canvasa:

Compact Beer Canning Innovation from Leibinger

Experience the world’s most compact beer canning machine, engineered in Germany with patented counter-pressure technology. Designed for craft brewers and small producers, Canvasa fits on a standard Euro pallet footprint—ideal for flexible, space-efficient setups anywhere, anytime.

Key Features:

- Ultra-Compact Design: Semi-automatic filler with a minimal 1m x 1.2m footprint for easy integration into any production space.

- Gentle Filling Precision: Patented counter-pressure system fills carbonated and non-carbonated beverages with low oxygen pickup, preserving flavor and quality.

- Modular Expandability: Add-ons like depalletizing tables, automatic rinsers, and labelers transform it into a fully automatic mini canning line for scalable efficiency.

- Made-in-Germany Reliability: Built for high-demand microfilling, ensuring consistent performance and minimal waste.

Invasa:

Bottle Filling Machine

The INVASA, developed by Leibinger, is the world’s most compact, fully automatic bottle filling machine with integrated counter-pressure technology and crown cork stopper, designed for efficient and space-saving filling in smaller production facilities.

Key Features:

- Compact Design: Fits on a small shipping pallet, ideal for limited spaces.

- Flexible and Mobile: Easily integrates into various production environments.

- Fully Automatic: Precisely fills carbonated and non-carbonated products with minimal oxygen input.

- Integrated Crown Capper: Ensures seamless processing and maximum efficiency.

- Expandable Options: Add labeler, packaging tables, automatic height adjustment, or semi-automatic depalletizer for a mini production line.

- Versatile: Supports multiple bottle formats, perfect for start-ups and beverage producers scaling up or testing new products.

- Hygienic and Robust: Easy maintenance by in-house staff.

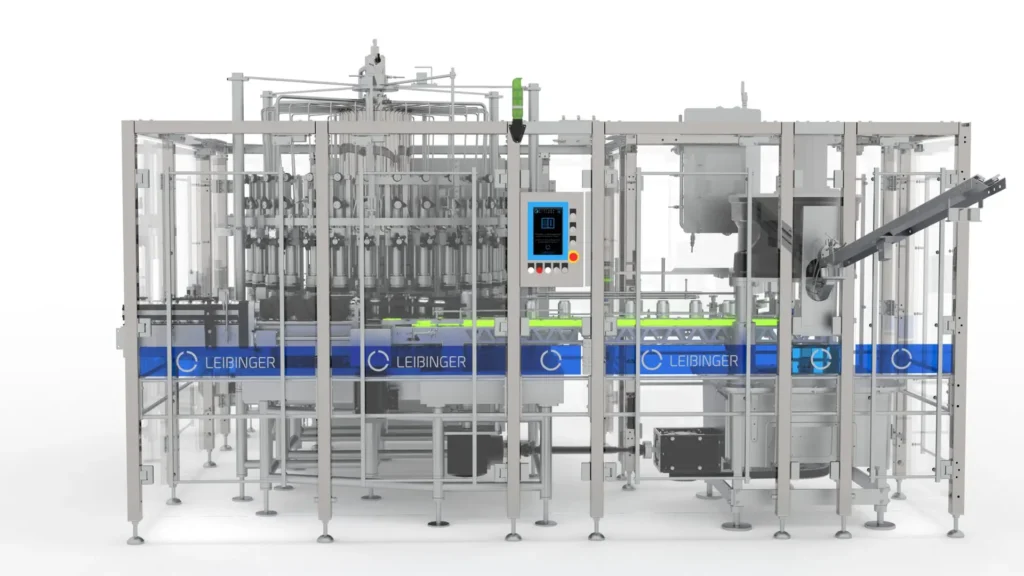

Multima LC:

Canning Machine

The Multima LC, developed by Leibinger, is a classic long-tube filler for carbonated beverages in cans, handling all common formats (SLIM, SLEEK, STANDARD) and non-carbonated beverages via nitrogen drop system, with integrated seamer for minimum oxygen pickup.

Key Features:

- Versatile Filling: Handles carbonated and non-carbonated beverages.

- Can Format Compatibility: Supports SLIM, SLEEK, and STANDARD cans with form parts.

- Integrated Seamer: Located at filler outlet for seamless operation.

- Low Oxygen Pickup: Achieved through well-designed gassing devices.

- Hygienic Design: Open construction compliant with hygienic standards.

- Easy Maintenance: Mechanical build allows annual service by experienced technicians.

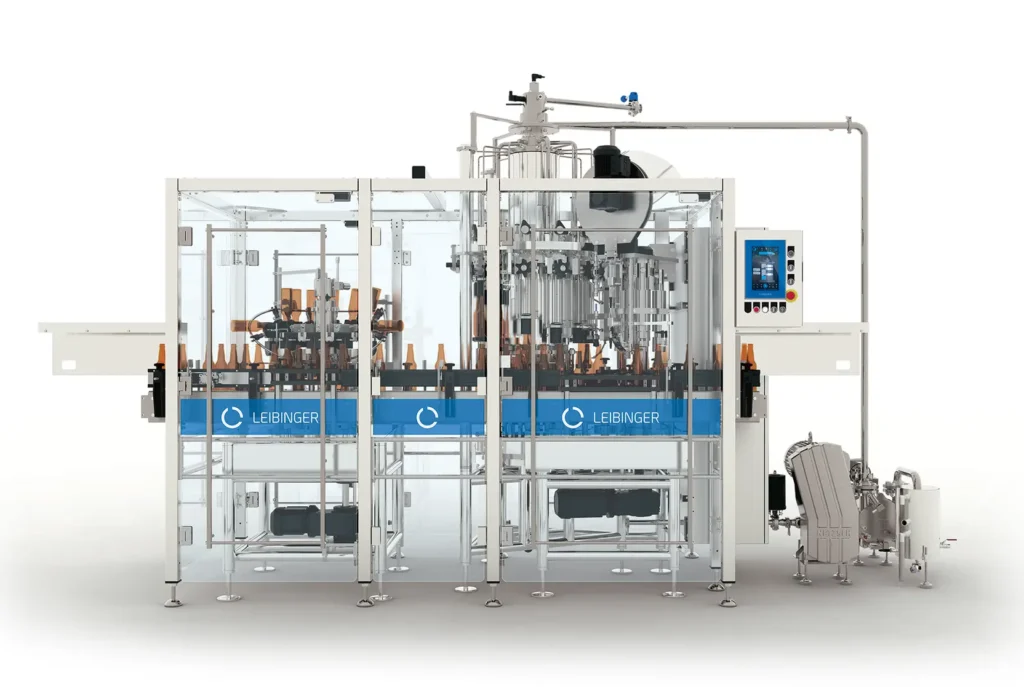

Multima L/K:

Bottling Machine

The Multima L/K, developed by Leibinger, uses counterpressure technology for filling carbonated products like beer, soft drinks, and mineral water, with integrated vacuum technology for low oxygen uptake in bottles, available as long-tube (L) or short-tube (K) fillers.

Key Features:

- Versatile Filling: Ideal for carbonated products with low oxygen uptake.

- Long-Tube (L) or Short-Tube (K): Long-tube for few bottle types; short-tube for frequent format changes with adjustable height.

- Optional Equipment: Integrated rinser for new glass, crown capper, or screw capper.

- Multi-Stage Vacuum Technology: Enables bottling with minimal oxygen content.

- Hygienic Design: Open construction compliant with EHEDG standards.

- Easy Maintenance: Mechanical build allows annual service by experienced technicians.

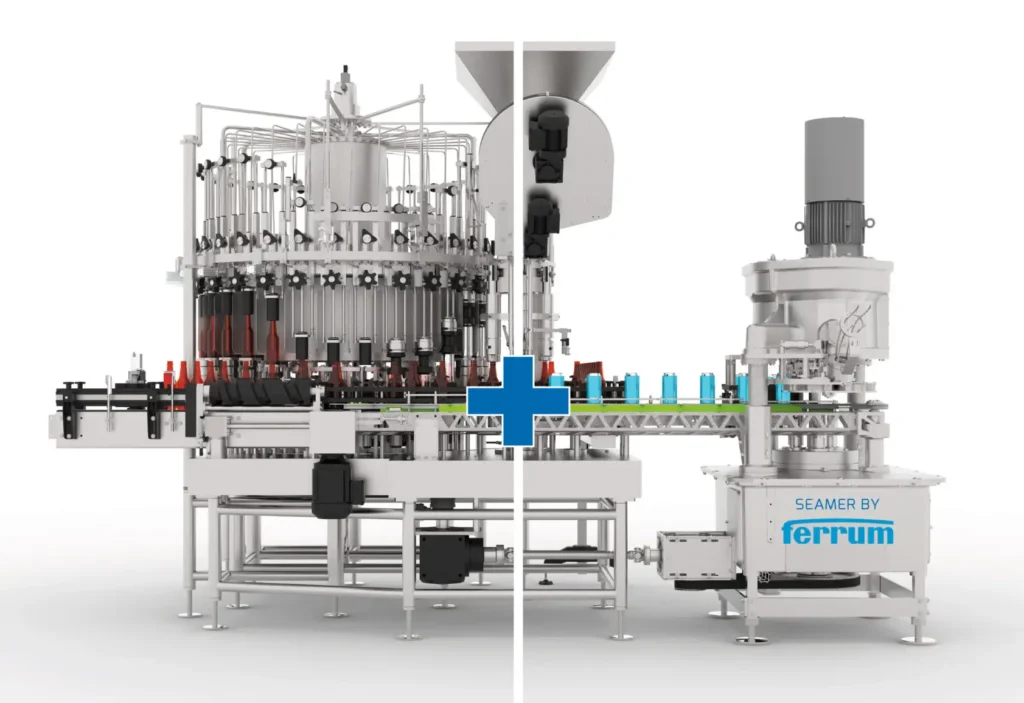

Multima 2in1:

Combined Bottling and Canning Machine

The Multima 2in1, developed by Leibinger, is a counter-pressure long-tube filler that seamlessly switches between bottling and canning modes in under an hour, ideal for producers of beer, soft drinks, sparkling wine, and champagne.

Key Features:

- Dual Functionality: Fills both bottles and cans with quick mode switching.

- Versatile Formats: Supports various bottle and can sizes.

- Optional Equipment: Includes can seamer; optional rinser, crown capper, or screw capper.

- Shared Infeed: Uses same peripherals for bottles and cans, with separate outlets.

- Hygienic Design: Open construction meets EHEDG standards.

- Easy Maintenance: Mechanical build allows annual service by experienced technicians.